Where Innovation Meets Texture: The Craft of Premium Quartz Slab Manufacturing

Quartz has become the material of modern design—sleek, strong, and precise.

Behind every perfectly uniform slab lies a complex dance of engineering, chemistry, and craftsmanship.

At Stonesale , the process of quartz slab manufacturing is treated as a science—where raw mineral meets automation to deliver surfaces that look flawless, feel natural, and last for decades.

Unlike natural granite or marble, quartz slabs are engineered composites, carefully formulated to achieve exact color tone, density, and performance.

This allows architects and designers to combine consistency with creativity—making quartz the go-to material for high-traffic, high-impact, and high-style environments.

How Quartz Slabs Are Made: The Manufacturing Process

Every quartz slab begins not in a quarry, but in a precision-controlled factory environment.

The process involves selecting, mixing, compressing, and curing minerals under specific pressure and temperature conditions.

🧱 Step-by-Step Manufacturing Flow

| Stage | Description | Stonesale Standard |

|---|---|---|

| 1. Raw Material Selection | 93–94% pure crushed quartz mixed with 6–7% polymer resin and pigments | Sourced from silica-rich mines with <0.1% impurities |

| 2. Mixing & Pigmentation | Uniform blending using vacuum mixers to remove air pockets | Optical scanning ensures tone consistency |

| 3. Molding & Compaction | Vacuum vibro-compression under 100 tons of pressure | Homogeneous density across slab |

| 4. Curing (Oven Baking) | Heated at 85–100°C for polymerization | Controlled for 45 minutes to stabilize internal structure |

| 5. Polishing & Calibration | 20-stage diamond polishing to achieve mirror or matte finishes | ±0.2mm thickness tolerance |

| 6. Quality Testing | Density, hardness, and absorption testing per ASTM standards | ISO 9001:2015 certified facility |

Each stage is digitally monitored for temperature, vibration frequency, and pigment dispersion—creating consistent slabs up to 3200×1600mm in size.

The Technical Strength Behind Engineered Quartz

Quartz combines natural hardness with engineered precision, giving it properties that outperform many natural stones in specific contexts.

| Property | Average Value | Architectural Advantage |

|---|---|---|

| Hardness (Mohs) | 7 | Scratch and cut resistance |

| Water Absorption | <0.02% | Hygienic and non-porous |

| Flexural Strength | 35–45 MPa | Ideal for large unsupported spans |

| Heat Resistance | Up to 180°C | Kitchen and hospitality use |

| Color Uniformity | 98% visual match | Perfect for multi-unit installations |

Unlike marble, quartz does not require sealing and remains resistant to staining from coffee, wine, or oil—making it an easy-care surface for long-term use.

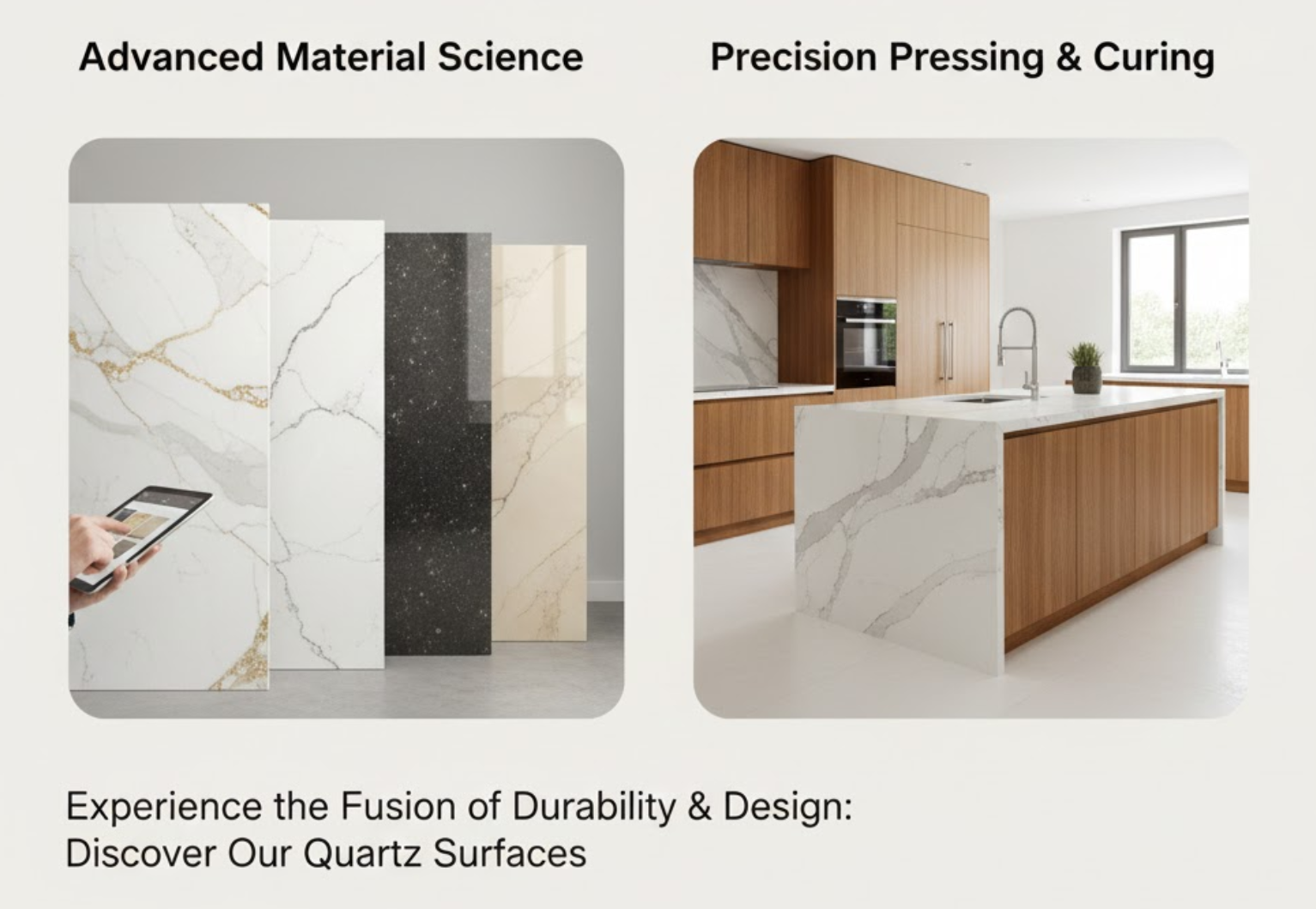

Aesthetic Engineering: Color and Finish Design

In architectural projects, quartz slabs serve not only as surfaces—but as visual anchors that define spatial tone.

Stonesale design team engineers over 120+ color tones, from minimalist whites and industrial greys to marble-inspired veined patterns.

Common Surface Finishes

-

Polished Quartz: Glossy, reflective, enhances color depth.

-

Honed Quartz: Matte finish, ideal for low-glare workspaces.

-

Leathered Quartz: Subtle texture that mimics natural touch.

-

Veined or Calacatta Quartz: Artificial veining resembling natural marble for luxury spaces.

Using digital pigment distribution systems and infrared curing calibration, Stonesale ensures tone consistency across production batches—critical for multi-floor hotel or commercial installations.

Applications Across Design and Construction

Quartz slabs are used in both functional and aesthetic roles:

-

Kitchen Countertops & Islands – Non-porous, stain-resistant, and low-maintenance.

-

Bathroom Vanity Tops – Resistant to humidity and cosmetic products.

-

Wall Cladding & Flooring – Seamless, large-format finishes with precise alignment.

-

Retail & Hospitality Interiors – High-luxury visual textures combined with durability.

-

Laboratory & Healthcare Environments – Hygienic, chemical-resistant surfaces.

Each Stonesale slab is pre-calibrated for custom fabrication, ensuring cutting accuracy and edge consistency at the client’s installation site.

How to Choose the Right Quartz Slab for Your Project

| Selection Factor | Why It Matters | Stonesale Recommendation |

|---|---|---|

| Application Environment | Impacts durability and finish | Polished for dry areas, honed for humid or bright spaces |

| Color Coordination | Defines mood & tone | Neutral base with soft veins for modern interiors |

| Thickness & Size | Affects load & stability | 20mm or 30mm depending on span and usage |

| Edge Design | Influences style & cleaning | Eased or beveled for modern designs |

| Budget & Maintenance | Controls long-term cost | Quartz requires minimal upkeep—ideal for high-traffic areas |

StoneSale offers 3D simulation previews, allowing clients to visualize color, pattern flow, and edge profile before mass production begins.

Q&A: Professional Insights on Quartz Manufacturing

Q: What makes quartz slabs more stable than natural stone?

Engineered quartz has uniform density and controlled resin bonding, eliminating natural fissures found in granite or marble.

Q: Are quartz slabs heatproof?

Quartz can withstand up to 180°C, but direct thermal shock (hot pots or pans) should be avoided. Using trivets maintains surface longevity.

Q: What quality standards does StoneSale follow?

All slabs comply with ASTM C97, EN 14617, and ISO 9001 certifications, including routine SGS inspections before export.

Engineered to Endure, Designed to Inspire

Quartz manufacturing is the art of combining minerals and imagination.

At StoneSale, every slab is engineered to elevate the experience of space—stronger than natural stone, more precise than handmade surfaces, and infinitely more adaptable.

Discover more quartz slab solutions on our homepage

or reach our expert team for customized specifications here.